Stand:

Rockal

Stand:

Rockal

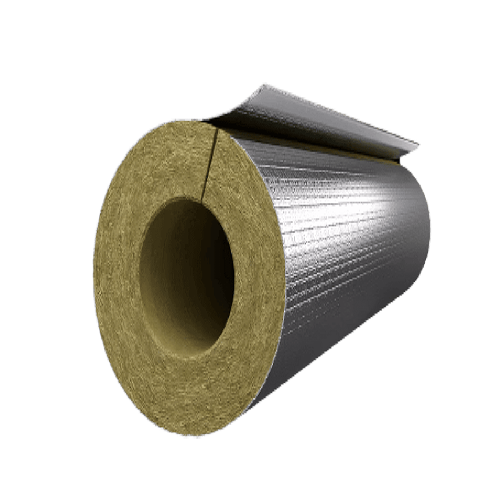

Rockwool Pipe insulation

Description

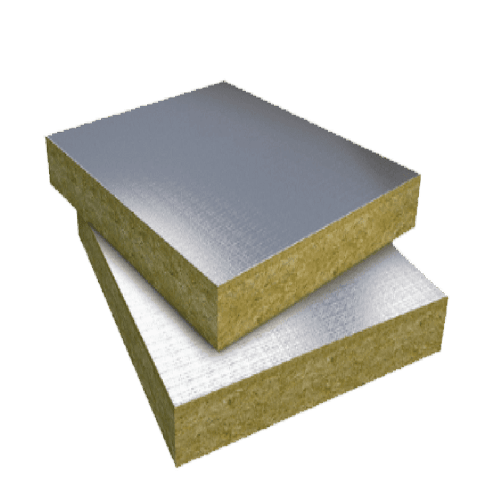

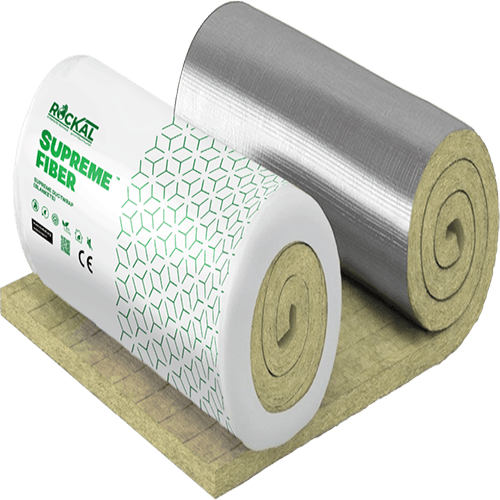

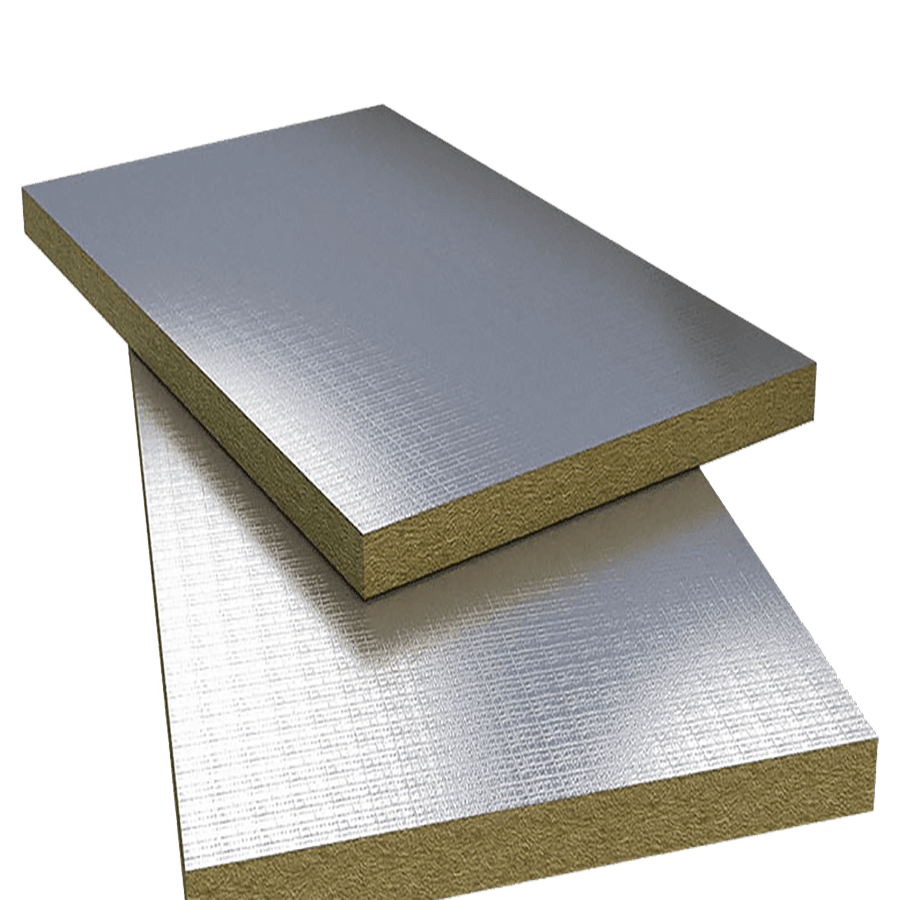

Rockwool pipe section is a type of insulation material made from rock minerals (such as basalt and slag) that have been melted at high temperatures and then spun into fibers. Rockwool pipe section is commonly used to insulate pipes and ductwork in building and HVAC systems. DESCRIPTION ROCKAL Performed Pipe Sections are made of rock wool fibers spun from molten basaltic rocks bonded together by a thermo-setting resin binder. The fibers are molded around the pipes of different standard diameters at the required thickness and dried to form rigid hollow cylinder insulation, which then is linearly slit to allow easy installation. Application Facing ROCKAL Rockwool Pipe Section comes non-faced or faced with reflective vapor barrier material (Reinforced Aluminum foil FSK). Fire Safety ROCKAL Rockwool fibers products are classified as Non-Combustible materials and follow the fire safety rating achievements: Available Products: Thermal Conductivity Technical PropertiesRockwool Pipe insulation

Advantages

Length (m.)

(Inch: schedule 40)

Condensation

The vapor diffusion of Rockal Rockwool is negligible it is considered zero compared to other insulation materials